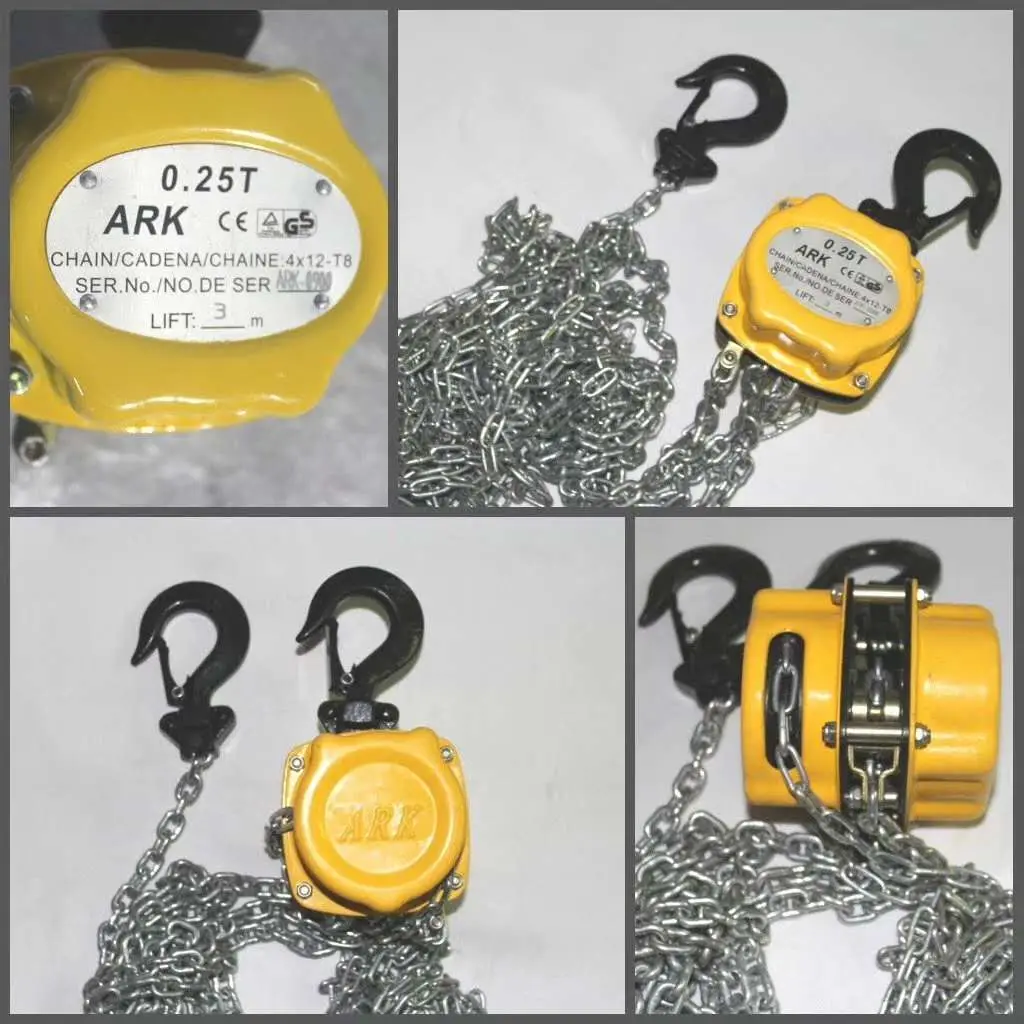

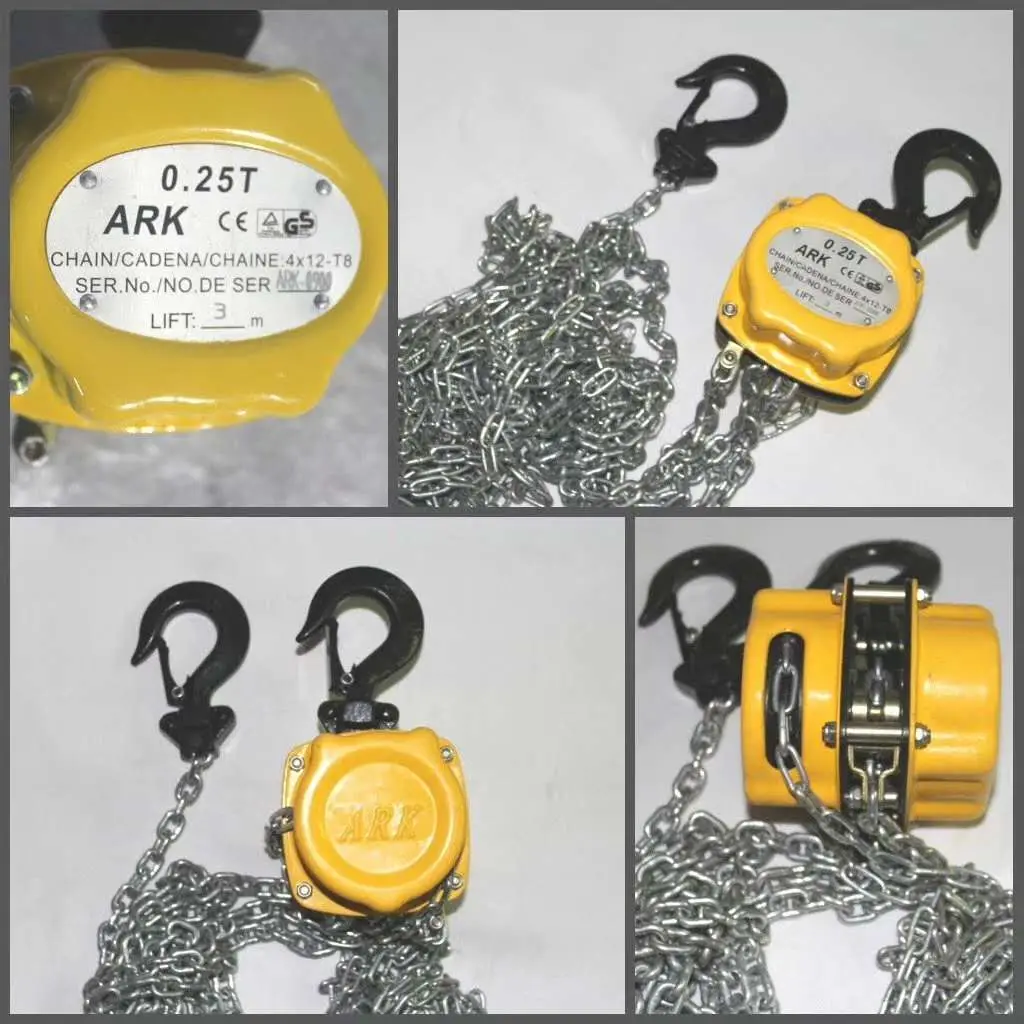

1. Mini Chain Block Manual Chain Winch

Unique designed quadrilateral appearance and thicker plate in beauty and long life.

High quality alloy forged hook in increased inner diameter is high strength.

Four supported points are more safe than traditional type hoists.

All gears in 20CrmoTi is in high strength and good toughness.

Double pawl spring mechanism increases break system

Premium no-slip nuts used for safety .

Ultra strong alloy G80 load chain.

The 0.25T baby hoist is in compact strcture, small volumn and light weight, widely used in high and narrow places in factory, mine and docks.

2. Chain hoist manufacturing process and details

Our factory have 1 quality department with 3 workmates to make 30% samples inspection to confirm every pitch spareparts meet quality standard. There is 1 load chain tension test line, 1 warehouse for some gears manufacturing, 2 assembly lines and well cooperated company for other spareparts.

Every chain hoist will be tested according to Euro standard EN13157+A1-2009 by 1.25 times dynamic load test and 4 times static load test.

3.Company service and technical support

Unique designed quadrilateral appearance and thicker plate in beauty and long life.

High quality alloy forged hook in increased inner diameter is high strength.

Four supported points are more safe than traditional type hoists.

All gears in 20CrmoTi is in high strength and good toughness.

Double pawl spring mechanism increases break system

Premium no-slip nuts used for safety .

Ultra strong alloy G80 load chain.

The 0.25T baby hoist is in compact strcture, small volumn and light weight, widely used in high and narrow places in factory, mine and docks.

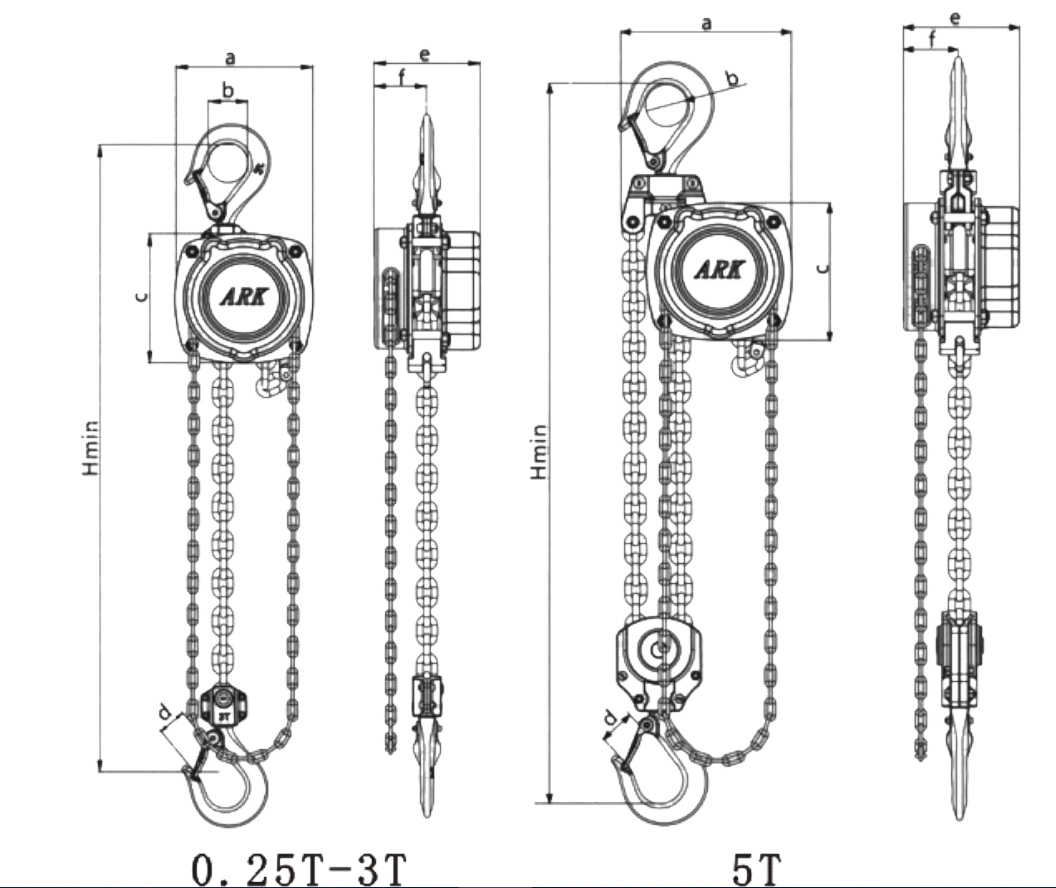

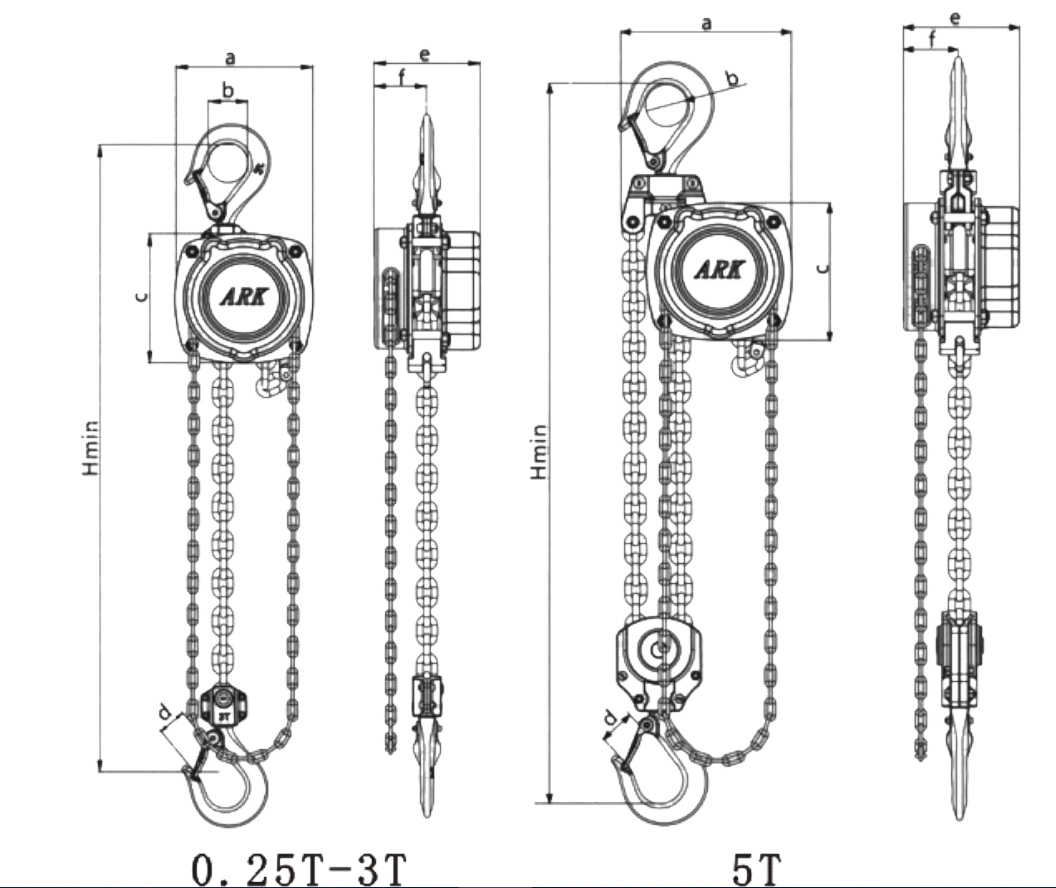

| Model | Capacity(kg) | Standard Lifting Height(M) | Force of Full load (N) | Test Load(kg) | Dia of load chain(mm) | Dimmension (mm) | Net Weight(kg) | |||||

| a | b | c | d | e | Hmin | |||||||

| DE-0.25 | 250 | 3 | 220 | 375 | 4*12 | 102 | 28 | 98 | 31 | 114 | 261 | 4.2 |

| DE-0.5 | 500 | 3 | 240 | 750 | 5*15 | 122 | 34 | 118 | 31 | 119 | 311 | 5.7 |

| DE-1 | 1000 | 3 | 305 | 1500 | 6*18 | 152 | 40 | 145 | 31 | 139 | 373 | 10.8 |

| DE-2 | 2000 | 3 | 360 | 3000 | 8*24 | 190 | 52 | 184 | 41 | 150 | 460 | 17.1 |

| DE-3 | 3000 | 3 | 370 | 4500 | 10*30 | 240 | 62 | 214 | 45 | 158 | 553 | 26.2 |

| DE-5 | 5000 | 3 | 390 | 7500 | 10*30 | 240 | 72 | 214 | 51 | 158 | 630 | 40 |

| DE-10 | 10000 | 3 | 430 | 15000 | 10*30 | 244 | 70 | 204 | 54 | 167 | 705 | 73.2 |

2. Chain hoist manufacturing process and details

Our factory have 1 quality department with 3 workmates to make 30% samples inspection to confirm every pitch spareparts meet quality standard. There is 1 load chain tension test line, 1 warehouse for some gears manufacturing, 2 assembly lines and well cooperated company for other spareparts.

Every chain hoist will be tested according to Euro standard EN13157+A1-2009 by 1.25 times dynamic load test and 4 times static load test.

3.Company service and technical support

- Samples can be offered by express. Costs will be reduced in orders.

- Our parts library can ensure timely and enough spare parts. Some free wearing parts can be offered according to order details.

- Our guaranty is 1 year for free maintenance.

- Training can be provided , such as design, customization,installation and after-sales use.

- OEM is welcomed.

- Completely quick feedback